Integrating fleet management with construction ERP systems is a game-changer for the construction industry. This integration streamlines operations and enhances project management. It centralizes data, providing a comprehensive view of resources and timelines.

Fleet management software, when integrated with ERP, offers real-time tracking of equipment and vehicles. This improves resource allocation and reduces downtime. The result is increased efficiency and cost savings.

Construction project managers and fleet managers benefit from improved communication and data-driven insights. These insights lead to better decision-making and project outcomes. Integration also reduces manual data entry, minimizing errors and saving time.

In this article, we explore the benefits and best practices of this integration. Learn how it can transform your construction operations and drive success.

Understanding Fleet Management with Construction ERP

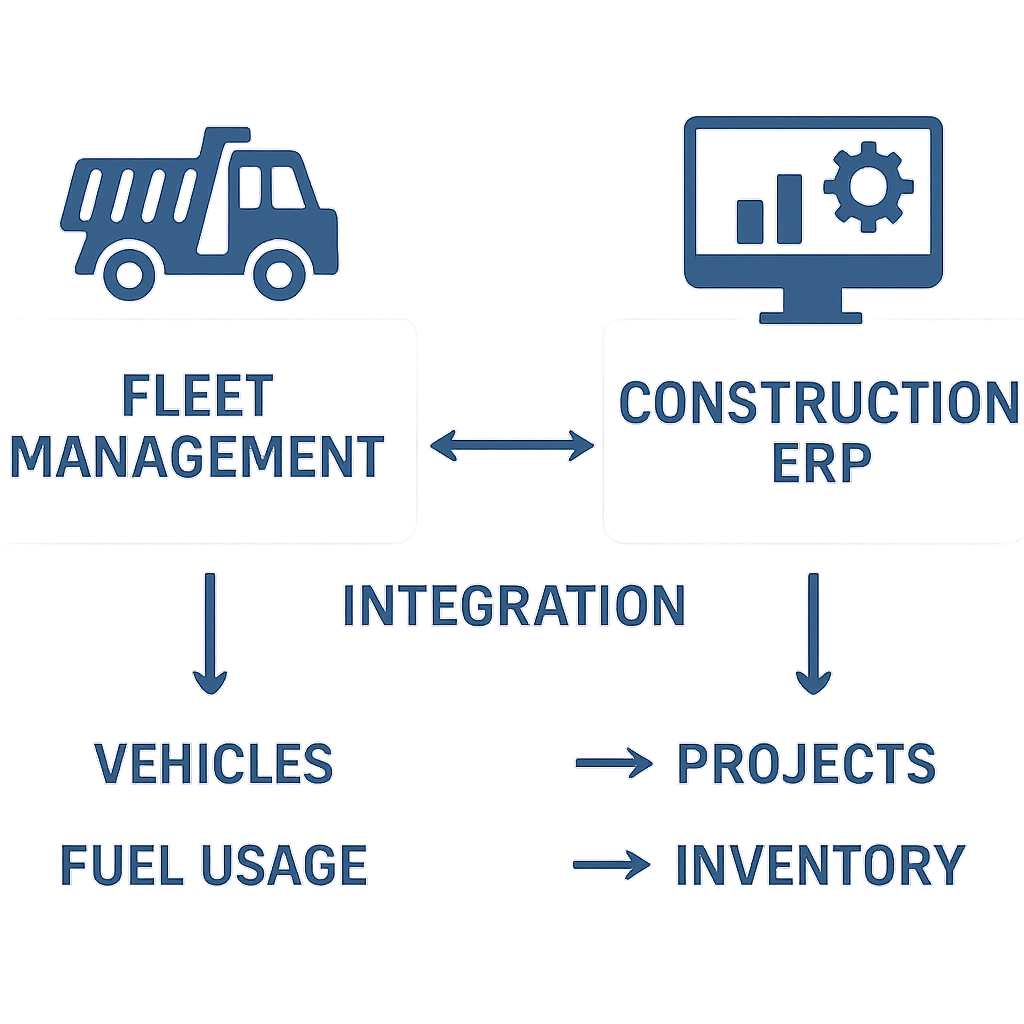

Fleet management and construction ERP integration merges two robust systems. Fleet management software optimizes the use of vehicles and equipment. Construction ERP systems provide a centralized platform for managing project details.

This integration is crucial for construction companies seeking efficiency. It allows seamless data exchange between systems, enhancing visibility across projects. Managers gain comprehensive insights into fleet and project performance.

Advantages of integration include:

- Real-time tracking of assets

- Streamlined communication between teams

- Improved scheduling and maintenance

Integration is not just about technology but also process improvement. It connects various aspects of construction operations. The result is more efficient use of resources, reduced costs, and minimized downtime.

Why Integration Matters in Construction Project Management

Integration is vital in construction project management due to its impact on efficiency. It links fleet operations with project needs, ensuring all resources are used effectively. This coordination is key in meeting project timelines and budget constraints.

The harmony created by integration leads to fewer errors and less manual input. Automated systems facilitate seamless data transfer between fleet and project management modules, saving valuable time and minimizing mistakes. Such efficiency boosts overall project productivity and success rates.

Key reasons why integration matters include:

- Enhanced project visibility

- Reduced operational costs

- Improved resource allocation

Ultimately, integration strengthens the decision-making process. It provides project managers with real-time data, improving their ability to make informed choices. This data-driven approach optimizes resource allocation, resulting in improved project outcomes.

Key Benefits of Integrating Fleet Management with Construction ERP

Integrating fleet management with construction ERP brings significant advantages. It centralizes data, reducing chaos and improving workflow. Centralization facilitates more informed decision-making throughout the project lifecycle.

Resource allocation becomes more efficient with integration. Real-time tracking enables the more efficient use of equipment and vehicles. This visibility helps project managers optimize resource deployment.

Maintenance schedules improve through integrated systems. Fleet management software can predict and manage maintenance needs, reducing downtime. This proactive maintenance enhances overall productivity.

There are several other notable benefits:

- Improved project timelines

- Enhanced operational transparency

- Automated compliance reporting

Integration boosts communication between field and office staff. Enhanced communication reduces mistakes and accelerates project progress. Managers can quickly share updates, keeping everyone informed.

Additionally, integrated systems help to cut costs by tracking and reducing fuel usage. Efficient route planning reduces unnecessary fuel consumption. This not only saves money but also supports environmental goals.

Other financial benefits include:

- Lower operational costs

- Better budget management

- Increased fleet utilization

Lastly, integrating systems enhances customer satisfaction. Faster project delivery and fewer delays result in happier clients. These improvements can give companies a competitive edge in the industry.

How Integration Streamlines Operations and Data Flow

Integrating fleet management with construction ERP allows seamless data exchange. This integration breaks down data silos, creating a unified information flow. Employees can easily access real-time data, enhancing collaboration and decision-making.

Streamlined data flow minimizes duplication errors. Manual data entry often leads to inconsistencies and mistakes, which can be costly. Automation reduces these errors and saves time, allowing staff to focus on strategic tasks.

With this integration, key operational processes become more efficient. Information shared between teams aids effective planning. Workers can adapt quickly to project changes, maintaining smooth operation.

Key areas of operational improvement include:

- Data-driven decision-making

- Reduced manual entry

- Enhanced collaboration

Finally, improved data flow enables accurate performance tracking. Managers gain insights into equipment and project status. This visibility supports better resource management and project outcomes.

Enhancing Equipment Tracking and Resource Optimization

Integrating fleet management with construction ERP enhances equipment tracking capabilities. Real-time GPS and telematics data provide precise locations of equipment. Managers can allocate resources effectively, ensuring on-time project completion.

Resource optimization is crucial to reducing costs and enhancing project efficiency. Integrated systems track usage patterns, enabling more effective scheduling. Equipment downtime is minimized, increasing productivity.

An integrated approach also improves communication across teams. Sharing equipment status helps prevent scheduling conflicts. Timely data allows for responsive adjustments to resource allocation.

Resource optimization benefits include:

- Improved equipment allocation

- Minimized downtime

- Enhanced scheduling

Ultimately, these improvements lead to more efficient operations. Projects run smoothly, with fewer disruptions. This integration supports both project and financial goals.

Improving Maintenance, Safety, and Compliance

Integrating fleet management with construction ERP systems enhances maintenance efficiency. Predictive maintenance features alert managers about potential equipment issues before they lead to downtime. This proactive approach increases equipment longevity and reduces repair costs.

Safety is another critical benefit of this integration. Systems can monitor vehicle conditions and driver behavior in real time. Alerts for improper handling or hazardous conditions protect workers and equipment. Safety initiatives are bolstered, reducing the risk of accidents.

Compliance management becomes more streamlined with integrated systems. Automated records ensure adherence to regulatory requirements without extensive manual effort. This results in reduced penalties and smoother audits.

Key advantages include:

- Proactive maintenance alerts

- Real-time safety monitoring

- Streamlined compliance management

Financial and Sustainability Advantages

Integrating fleet management with construction ERP systems offers significant financial benefits. Costs are controlled through optimized resource use and reduced fuel consumption. Economic data from fleets link seamlessly to project budgets.

Sustainability goals benefit from data-driven insights. Efficient resource allocation minimizes waste and promotes environmentally friendly practices. Monitoring fuel usage and emissions advances green initiatives.

Operational efficiency supports both financial stability and sustainability efforts. When systems work together, businesses see savings and improved environmental outcomes. This creates a virtuous cycle of improved fiscal and environmental performance.

Key financial and sustainability benefits include:

- Cost control through optimized usage

- Reduced emissions and fuel savings

- Enhanced resource allocation

Best Practices for Successful Integration

Successful integration of fleet management with construction ERP requires strategic planning. Define clear goals to guide the integration process and ensure alignment with business objectives.

Engage all relevant stakeholders early in the process. This includes IT teams, project managers, and field staff. Their input and buy-in are crucial for a smooth transition.

Select compatible software solutions to facilitate seamless integration. Consider systems that offer flexibility and scalability to support future growth and technology updates.

Provide comprehensive training for staff on the new integrated systems. This ensures that employees are comfortable and capable of using the technology effectively.

Key practices for success include:

- Setting clear integration goals

- Involving stakeholders early

- Choosing compatible software

Training tips:

- Offer hands-on sessions

- Provide ongoing support

- Encourage feedback and adaptation

Common Challenges and How to Overcome Them

Integrating fleet management with construction ERP can present several challenges. These may include data integration issues and resistance from staff. Address these proactively to ensure smooth integration.

To overcome these hurdles, consider strategies such as:

- Conducting thorough system tests

- Encouraging open communication

- Providing change management support

Implementing these solutions can help address common challenges, resulting in a more effective and streamlined integration process. By focusing on preparation and communication, you can mitigate potential disruptions.

Choosing the Right Fleet Management Software and ERP Solutions

Selecting suitable fleet management software and ERP solutions is critical for seamless integration. Ensure the software you choose aligns with your business needs and supports scalability.

Consider the following factors when choosing:

- Compatibility with existing systems

- Ease of use for employees

- Vendor support and training options

By evaluating these aspects, you can better ensure that your chosen solutions support both current operations and future growth.

Real-World Examples of Risk Mitigation

Many construction companies have successfully deployed vehicle telematics within their existing fleet.

Utilizing vehicle telematics, combined with dash cameras, provides drivers with an enhanced awareness of their surroundings. This awareness increases the driver’s attention, vehicle management, and road conditions – while simultaneously reducing the risk of accidents. This two-fold approach converges to provide fleet operators with an opportunity to lower insurance costs and premiums.

Each of these successes demonstrates the potential benefits of integrating these technologies effectively.

Future Trends: Digital Transformation and Emerging Technologies

The landscape of construction is rapidly changing. Digital transformation is a key driver of this evolution. Emerging technologies are making a substantial impact.

Consider these trends that could shape the future:

- Connect IoT devices for real-time data collection.

- Use AI to generate predictive maintenance.

- Cloud-based solutions for flexible scalability.

These innovations can drive efficiencies and offer significant competitive advantages.

Conclusion: Unlocking the Full Potential of Integrated Construction Operations

Integrating fleet management with construction ERP systems is transformative. It creates streamlined processes and improved resource management. The benefits extend to project efficiency and cost savings.

Achieving successful integration requires careful planning and strategic implementation. Future-proof your operations by embracing digital transformation and leveraging emerging technologies. This approach ensures sustainable growth and adaptability in a competitive market. By integrating these systems, businesses can unlock their true operational potential.